Resource Conservation and Circulation

Targets and Results

Progress of Waste Indicators and Breakdown by Type

Container and Packaging Usage Volume, Recycling Commission Volume (FY2024 Results) (tons)

| Containers and packaging materials used | Amount consigned for reuse/recycling | |

|---|---|---|

Plastic |

584 | 202 |

Paper |

151 | 4 |

Glass (transparent) |

35 | 6 |

Glass (brown) |

23 | 7 |

Initiatives for Resource Conservation and Circulation

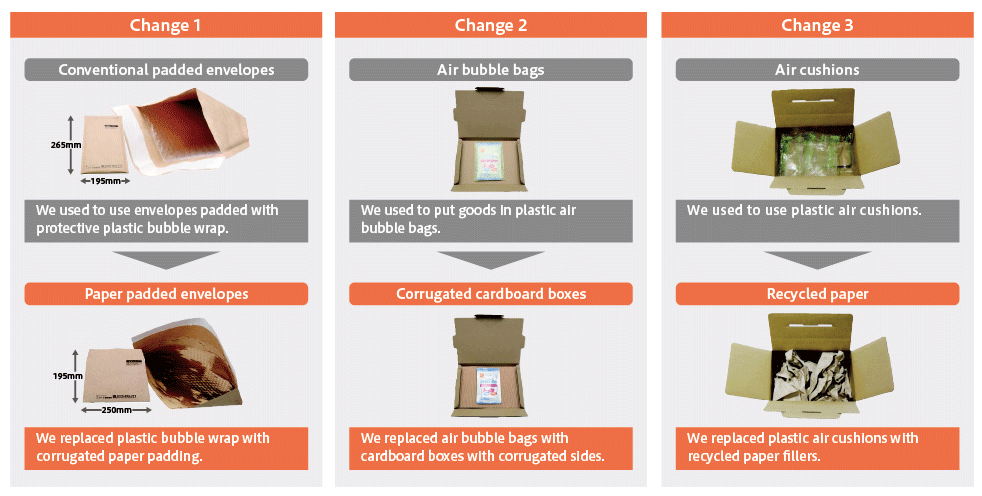

Initiatives to Reduce Plastic Usage

■Overview of 3R + Renewable Initiatives for Containers and Packaging

Measures |

Item |

Products concerned |

|---|---|---|

Reduce |

Change of packaging materials used for the delivery of products by mail order (from plastic to paper) * |

Healthcare goods through Shionogi Healthcare mail order service (with some exceptions) |

Change of material for trays (from plastic to paper) * |

All drugs provided in ampoules, vials, and tubes |

|

Change of thickness of eye drop containers (made thinner) |

All eye drops |

|

Change of thickness of PTP packaging materials (made thinner) |

Flomox Tablets, etc. |

|

Discontinuation of use of plastic cushioning materials for bottles |

rbetan Tablets, Baktar Combination Tablets, Fluitran Tablets |

|

Discontinuation of use of individual packaging banding film* |

Xofluza Tablets, Xocova Tablets, Symproic Tablets, etc. |

|

Discontinuation of Unit Cartons |

Lindelon Ointment Products, etc. |

|

Downsizing of Unit Cartons * |

Xofluza Tablets, Xocova Tablets, etc. |

|

Elimination of Rotational Stamp Printing (Ink Reduction and Waste Minimization) * |

Water-Soluble Predonin Injection, Lindelon Injection, Lindelon Suspension Injection |

|

Reuse Recycle |

Inscription of plastic container/packaging material identification marks * |

All products |

Pillow packaging made from mechanically recycled PET |

Symproic Tablets |

|

Promotion of the horizontal recycling of label mounts – “Resource Recycling Project” |

Label mounts to be affixed to ampoule injection products and shipping boxes |

|

Labels made from recycled PET (25% or more) |

Water-soluble Prednisone Injection, Rinderon Injection, Rinderon Suspension Injection |

|

Renewable |

Bottles made from biomass polyethylene |

Baktar Combination Tablets, Baktar mini Combination Tablets, Baktar Combination Granules, Cinal EX Pro Chewable Tablets, Almeta Ointment, Fulmeta Ointment, Rinderon-V, etc. |

PTP sheet* made from biomass polyethylene |

Cymbalta Capsules |

|

PTP banding film* made from biodegradable biopolymer “Green Planet” |

Symproic Tablets, etc. |

|

Biomass ink* |

Labels and individual packaging boxes for some products |

■ Initiatives by Shionogi Healthcare Co., Ltd.

Suppression of Petroleum-derived Plastic Usage

■ Bottles Made from Biomass Polyethylene*2

The SHIONOGI Group uses biomass bottles for Cinal EX Pro chewable tablets, Cymbalta capsules, Irbetan tablets, Pirespa tablets, Baktar combination granules, Baktar combination tablets, Baktar mini combination tablets, Almeta ointment, Fulmeta ointment, Rinderon-DP ointment, Rinderon-VG ointment, and Rinderon-V ointment. Biomass bottles (plant-derived polyethylene bottles) are packaging containers made of polyethylene derived from materials left over from sugarcane processing. Renewable polyethylene derived from sugarcane accounts for more than 90% of the raw material of our biomass bottles, which conform to the standards established by the Japan BioPlastics Association for biomass plastic identification labeling (the biomass plastic symbol mark is displayed on the product containers).*3

Switching from conventional petroleum-derived polyethylene bottles to biomass bottles can reduce CO2 emissions and conserve fossil fuel resources. We are currently conducting a technical study to gradually expand the use of biomass polyethylene to other product packaging.

■ PTP Sheets Made from Biomass Polyethylene*2

In addition to the above bottle packaging, plant-derived biomass polyethylene PTP sheets have been used for the Cymbalta capsules. These PTP sheets use biomass polyethylene derived from sugarcane for 25% of their raw material and conform to the standards established by the Japan BioPlastics Association for biomass plastic identification labeling (the biomass plastic symbol mark is displayed on the product containers).*3 Furthermore, we have reduced not only the GHG emissions but also the amount of waste generated by making the PTP sheets thinner than conventional ones. We are currently conducting a technical study to gradually expand the use of biomass polyethylene to other PTP sheets.

*2 Unlike conventional petroleum-derived polyethylene, biomass polyethylene is made from sugarcane processing residues. As sugarcane absorbs CO2 during its growth, CO2 emissions from the incineration of the resulting waste can be considered zero (carbon neutral).

*3 Biomass Plastic Identification Labeling System: Biomass plastic products (biomass plastics) contain a specified amount or more of organic (e.g., plant-derived) materials as plastic components. The Japan BioPlastics Association certifies products that meet its standards and permits the use of a symbol mark to help consumers easily identify biomass plastics.

■ PTP Banding Film Using Biodegradable Biopolymer Green Planet®

Green Planet® was used in the banding film for bundling PTP sheets, such as those for Symproic tablets. Green Planet® is a 100% biomass-derived biodegradable biopolymer that decomposes easily in soil and seawater, ultimately returning to carbon dioxide and water. This contributes to solving environmental pollution issues, including marine plastic waste caused by one-way (disposable) plastics.

Approach to Resource Conservation and Circulation

■ Horizontal Recycling of Label Mounts: “Resource Recycling Project”

Shionogi Pharma Co., Ltd. participates in the “Resource Recycling Project,” which promotes the horizontal recycling*4of label mounts*5 that were previously discarded during the manufacturing process. Since 2023, the company has been collecting and recycling used label mounts.

This initiative has been applied to label mounts used for the SHIONOGI Group’s prescription drugs (nine ampoule injection products and shipping labels for packaging boxes), contributing to reductions in industrial waste generation and GHG emissions and improvements in the waste plastic recycling rate.

*4 Horizontal recycling refers to the recycling of used products into raw materials to manufacture the same type of products.

*5 Label mounts (release paper, separator) are the backing sheets used to protect the adhesive side of labels. Because of the resin coating that prevents adhesion, they are generally difficult to recycle.

■ Pillow Packaging Using Mechanically Recycled PET Film

The aluminum pillow packaging for Symproic tablets uses a mechanically recycled PET film, which contains over 80% recycled PET derived from used PET bottles that have been sorted, crushed, washed, and treated under high-temperature decompression.

This packaging maintains product quality while reducing CO2 emissions and conserving fossil resources. Technical studies are underway to expand the use of recycled PET and monomaterial packaging to other products.

Reduction of Paper Resources

SHIONOGI Group’s administrative offices, Shionogi Business Partner Co., Ltd., and the labor union of Shionogi & Co., Ltd. are implementing paper resource conservation initiatives.

For Linderon ointment (three products), the switch from individual packaging boxes to shrink packaging*6 has contributed to reductions in GHG emissions and waste generation compared with conventional packaging.

*6 Shrink packaging uses the property of the film that contracts when heated to conform to the container shape.

and changed to shrink packaging

Clean-up Activities