Resource Conservation and Circulation

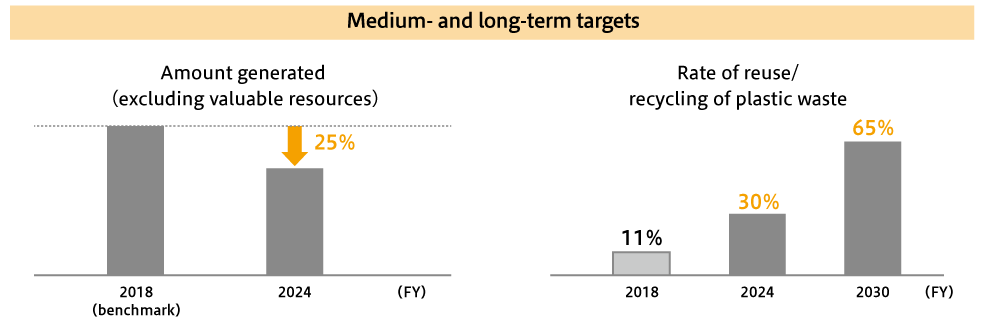

Targets and Results

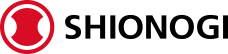

Medium- and long-term targets

Containers and packaging materials used and amount consigned for reuse/recycling (FY2023 results) (tons)

| Containers and packaging materials used | Amount consigned for reuse/recycling | |

|---|---|---|

Plastic |

510 | 171 |

Paper |

105 | 3 |

Glass (transparent) |

35 | 7 |

Glass (brown) |

18 | 5 |

Resource Conservation and Circulation Initiatives

Establishment of new medium- and long-term targets

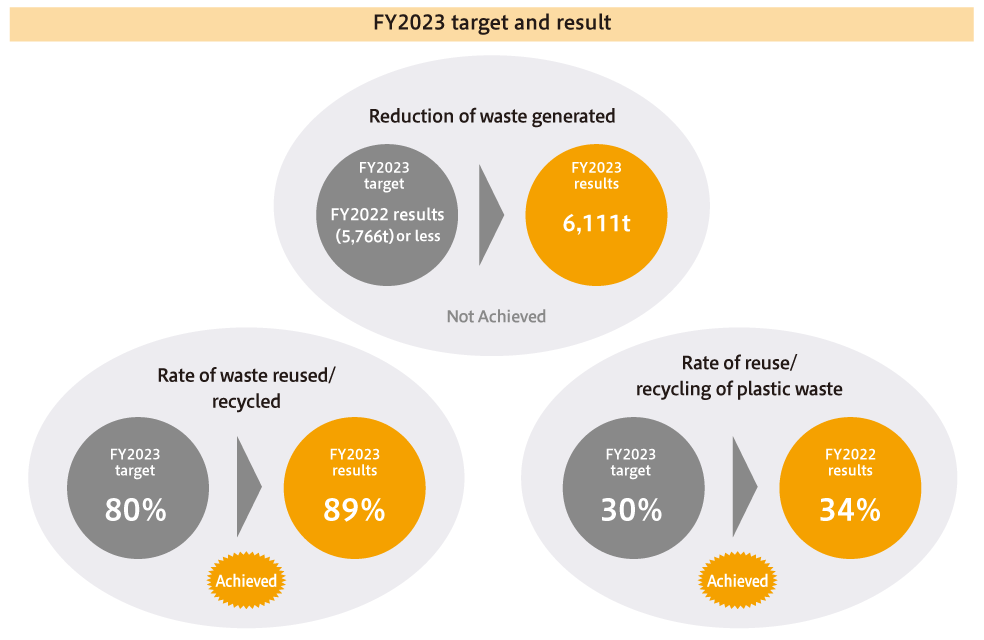

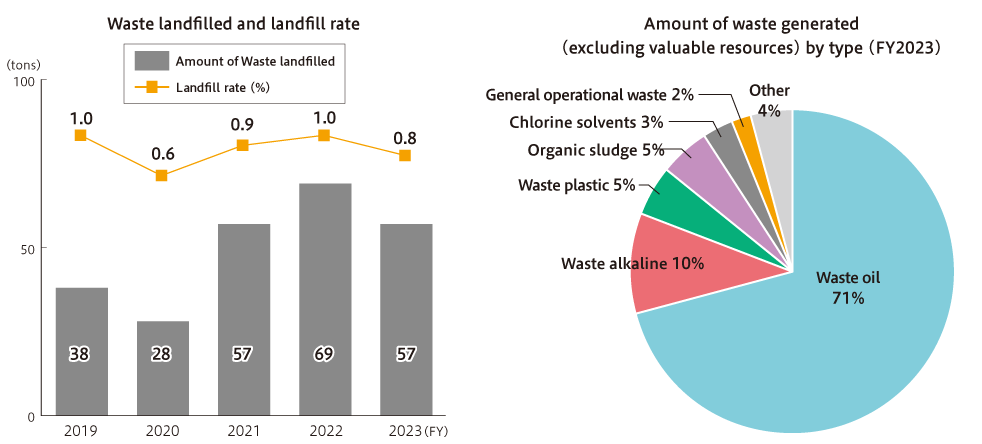

SHIONOGI has set medium-term targets for resource conservation and circulation as “a waste reduction rate of 25% or more (FY2018 benchmark), a waste recycling rate of 80% or more, and a waste plastic recycling rate of 30% or more in FY2024,” and “restrict plastic use in products,” and has promoted measures that lead to resource conservation and circulation at each operating site. Of these four targets, the target for “waste reduction rate” had not been achieved in recent years due to an increase in manufacturing volume resulting from business expansion. In light of the above, when reviewing the SHIONOGI EHS Action Targets in FY 2023, we set two new medium- and long-term targets that would not be affected by an increase in manufacturing volume due to business expansion: “a waste plastic recycling rate of 65% or more and a landfill rate of 1% or less in FY2035.”*2

With the two new medium- and long-term targets, SHIONOGI will work harder than ever to conserve and recycle resources.

Strategies for controlling plastic waste

■3R (Reduce, Reuse, and Recycle) + Renewable initiative concerning containers and packaging materials

Measures |

Item |

Products concerned |

|---|---|---|

Reduce |

Change of packaging materials used for the delivery of products by mail order (from plastic to paper) |

All healthcare goods through Shionogi Healthcare mail order service |

Change of material for trays (from plastic to paper) |

All drugs provided in ampoules, vials, and tubes |

|

Change of thickness of eye drop containers (made thinner) |

All eye drops |

|

Change of thickness of PTP packaging materials (made thinner) |

Flomox Tablets, etc. |

|

Discontinuation of use of plastic cushioning materials for bottles |

Irbetan Tablets, Baktar Combination Tablets, Fluitran Tablets |

|

Reuse Recycle |

Inscription of plastic container/packaging material identification marks |

All products |

Adoption of mechanically recycled PET film |

Symproic Tablets |

|

Horizontal recycling of label mounts “Resource Recycling Project” |

Ampoule injection products, packaging boxes | |

Renewable |

Adoption of biomass bottles (plant-derived polyethylene bottles) |

Cymbalta Capsules, Irbetan Tablets, Pirespa Tablets, Baktar Combination Tablets, Baktar mini Combination Tablets, Baktar Combination Granules, Cinal EX Pro Chewable Tablets, Almeta Ointment, Fulmeta Ointment, Rinderon-V, etc. |

| Adoption of biomass ink | Labels and individual packaging boxes for some products |

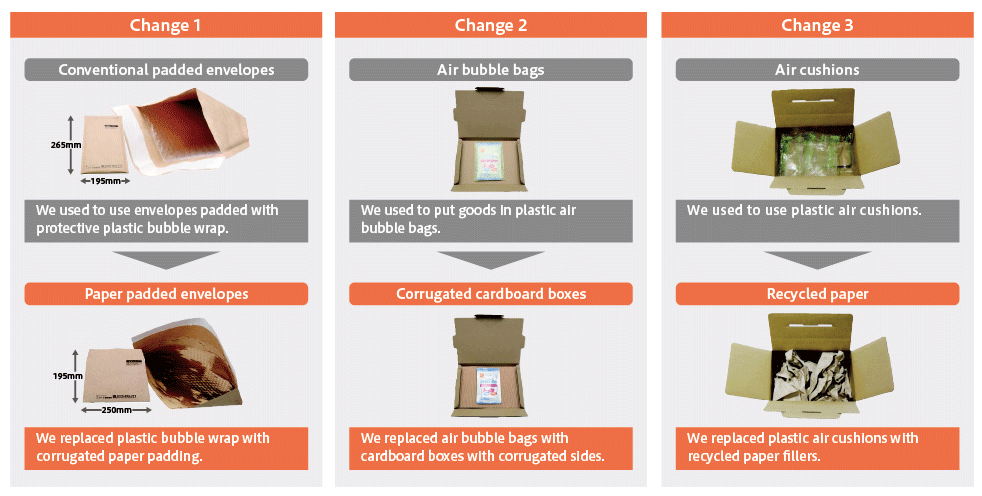

■ Initiatives by Shionogi Healthcare Co., Ltd.

For its mail order service “Shionogi Healthcare ONLINE,” Shionogi Healthcare Co., Ltd. has changed all of the plastic materials used for product delivery to paper-based packaging since FY2019. Through this initiative, we have realized packaging that is not only environmentally friendly but also helps eliminate the need for customers to separate waste.

■ Mechanically recycled PET film

SHIONOGI uses mechanically recycled PET (polyethylene terephthalate) film in the packaging (aluminum bags) of Symproic.

Mechanically recycled PET film derives from used PET bottles that undergo several steps: selection, crushing, cleansing, and high-temperature decompression.

The replacement of virgin PET film in the outermost layer of the aluminum bags with mechanically recycled PET film results in reduced CO2 emissions and fossil fuel conservation while maintaining the quality of the packaged products. This contributed to reducing CO2 emissions by 0.25 tons compared to conventional film in FY2023. We are currently conducting a technical study to gradually expand the use of mechanically recycled PET film to other product packaging materials.

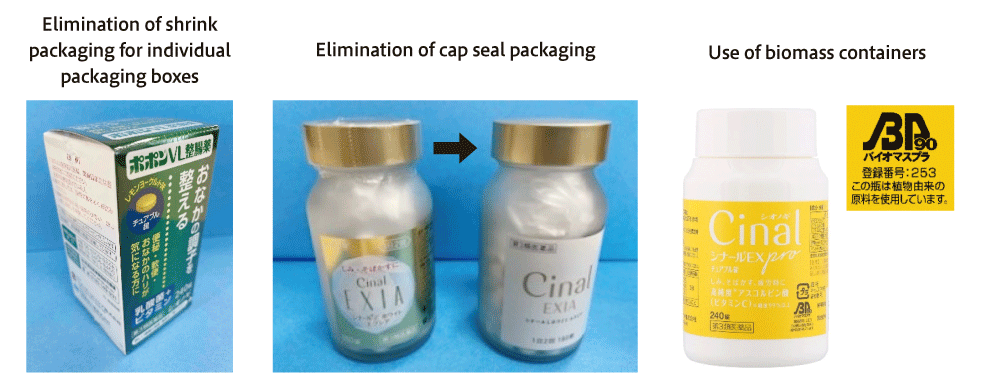

■ Biomass bottles

SHIONOGI uses biomass bottles for Cinal EX Pro chewable tablets, Cymbalta, Irbetan, Pirespa, Baktar combination granules, Baktar combination tablets, Baktar mini combination tablets, Almeta, Fulmeta, Rinderon-DP, Rinderon-VG, and Rinderon-V. Biomass bottles (plant-derived polyethylene bottles) are packaging containers made of polyethylene derived from materials left over from sugarcane processing. Renewable polyethylene derived from sugarcane accounts for more than 90% of the raw material of our biomass bottles, which conform to the standards established by the Japan BioPlastics Association for biomass plastic identification labeling (The biomass plastic symbol mark is displayed on the product containers).*3 By switching from conventional petroleum-derived polyethylene bottles to biomass bottles, we can reduce CO2 emissions and conserve fossil fuel resources. This contributed to reducing CO2 emissions by 42.3 tons compared to conventional bottles in FY2023. We are currently conducting a technical study to gradually expand the use of biomass polyethylene to other product packaging.

In-house reuse/recycling of resources

■ Reuse of organic solvents

■ Horizontal recycling of label mounts under the “Resource Recycling Project”

Shionogi Pharma Co., Ltd. collects and recycles label mounts under the Resource Recycling Project, which promotes horizontal recycling*4 of label mounts*5 that were previously discarded in the manufacturing process.

This initiative has been gradually applied to SHIONOGI’s prescription drugs (shipping labels for the packaging boxes of nine types of ampoule injections), contributing to a reduction in industrial waste generated (approx. 0.7 tons/year), an improvement in the waste plastic recycling rate, and a reduction in CO2 emissions (approx. 0.6 tons/year).

*4 Recycling that processes used products into raw materials to recreate the same type of products

*5 Label mounts (release paper, separator) to protect the adhesive side of the label. It is generally difficult to recycle label mounts because they are coated with a resin material to prevent them from adhering to the label glue.

Reduction of paper resources

SHIONOGI’s administrative offices, Shionogi Business Partner Co., Ltd., and the labor union of Shionogi & Co., Ltd. are working to conserve paper resources.

For products, in line with the revision of the Pharmaceuticals and Medical Devices Act*6 (for digitization of package inserts), we have abolished paper package inserts enclosed with products (all products are now compliant). Furthermore, for Linderon (three types of products), by changing from individual packaging boxes to shrink packaging,*7 we contributed to a reduction of 6.0 tons of paper resources in FY2023 (a reduction in CO2 emissions of 0.48 tons) compared to conventional products.

*6 Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices

*7 Packaging that uses the property of film that shrinks when heated to conform to the shape of the container

and changed to shrink packaging

Clean-up activities

Environmental pollution caused by marine plastic waste has become a major global issue. Marine plastic waste can partly be traced back to plastic waste generated overland and carried into the sea by rain and wind via rivers. Employees at SHIONOGIʼs respective operating sites participate in clean-ups along the surrounding roads and other such initiatives organized in the local communities. Thus, we are working to contribute to the beautification of local areas and raise employee awareness of the environment and resource circulation.