Occupational Health and Safety

Based on the descriptions for occupational health and safety in the SHIONOGI Group EHS Policy and EHS Code of Conduct, we aim to achieve zero work-related fatal accidents, lost-time injuries, and work-related illnesses. We are continuously working to build an appropriate management system and improve the chemical substance management system, which poses a high risk for health and safety management in order to ensure the safety and health of our employees and create a comfortable working environment.

Governance Structure

The Environmental, Health, and Safety (EHS) initiatives of the SHIONOGI Group are overseen by the Chief EHS Officer, appointed as the Senior Executive Officer of Sustainability Management. The SHIONOGI Group Companywide EHS Committee, chaired by the Chief EHS Officer, includes representatives from each operating site and the presidents of the group companies, all of whom serve as EHS officers.

The Corporate Officer in charge of EHS heads the SHIONOGI Group Companywide EHS Committee, which comprises representatives from the group’s respective operating sites, who are appointed as personnel in charge of EHS, and presidents from Group companies. The SHIONOGI Group Companywide EHS Committee sets targets for EHS, identifies Environmental Materiality, and conducts management reviews, thereby promoting EHS activities. See the section Governance for details.

The SHIONOGI Group uses ISO 45001 (the international standard for occupational health and safety management systems) and in-house management systems established in conformity with it.

Each operating site manages the progress of safety and health objectives and conducts risk assessments to identify and control significant risks.

Concerning these matters, including risk management, are reviewed as a whole once a year by the SHIONOGI Group Companywide EHS Committee to verify the efficacy and suitability of its EHS initiatives.

Here is the current status of our certification under ISO 45001.

| Settsu Plant | Kanegasaki Plant | Tokushima Plant | Itami Plant | |

|---|---|---|---|---|

ISO45001 |

〇 |

〇 |

〇 |

〇 |

Results (Past 5 years)

| 2020 | 20121 | 2022 | 2023 | 2024 | |

| Occupational accidents (cases) | 7 | 4 | 9 | 2 | 1 |

| Of which those resulting in lost-time injulies(cases) |

1 | 1 | 1 | 0 | 0 |

| Frequency rate※1 | 019 | 0.20 | 0.21 | 0.24 | 0.13 |

| Severity rate※2 | 0.0046 | 0.0049 | 0.0021 | 0.0000 | 0.0000 |

Work-related injuries are reported, excluding accidents during commuting. Until fiscal year 2022, the data reflects cases from Shionogi & Co., Ltd. only. From fiscal year 2023 onward, the data includes cases from domestic consolidated entities.

- ※1Frequency rate: Frequency of accidents; the number of employees killed or injured in occupational accidents per one million total working hours

- ※2Severity rate: Severity of accidents; the number of work days lost due to occupational accidents per one thousand total working hours

To prevent occupational accidents involving chemical substances and realize a safety-secured working environment, we pursue continuous improvement with a focus on the development of the safety data sheet (SDS)-based management system and the enhancement of guidelines concerning chemical hazards.

In September 2022, a accident occurred in which one employee of a group company died due to a pressure door. The survey was conducted based on the procedures stipulated in the occupational health and safety management system and, SHIONOGI investigated all power door and shutter in all sites and installed safety devices on a part of doors and shutters with no safety system and implemented procedures to ensure the safe operation during opening and closing for preventing recurrence.

Audits

The SHIONOGI Group conducts audits of each operating site of the group and its suppliers using multiple approaches to check their EHS promotion status, as shown in the table below.

External audits |

Conducted by external accreditation organizations to verify that the group’s ISO 45001-certified management systems are operated in conformity with the standards |

|---|---|

Internal audits |

In-house self-inspection required under ISO 45001 conducted to confirm system suitability and status of conformity |

EHS audits |

Conducted by the division that supervises the SHIONOGI Group’s EHS initiatives, as directed by the management team, separately from internal audits, to check whether EHS activities in the SHIONOGI Group are appropriately implemented and maintained in compliance with the management systems while pursing continuous improvement |

EHS audits of suppliers |

Audits of the SHIONOGI Group’s suppliers of raw materials, intermediates, APIs, products, etc. conducted in compliance with the PSCI Principles |

Emergency preparedness

The SHIONOGI Group Risk Management Policy stipulates that in the event of a crisis, we should place top priority on protecting human life and ensuring safety, promptly take measures to minimize damage and prevent recurrence, and continue business operations as principles of action. To respond to emergencies, such as earthquakes, pandemics, and corporate scandals, we have established emergency response guidelines and manuals with a focus on respect for human life, consideration for and contribution to local communities, and business continuity. In anticipation of emergencies, we have established communication and reporting systems and regularly carry out emergency responsiveness training and review response procedures. In FY2024, disaster drills were conducted at each operating site, following a simulated scenario of an earthquake-triggered fire.

Education

In order to promote EHS activities, we believe it essential that individual employees be fully aware of environmental, health, and safety issues in connection with their own work and actively address them. In addition to EHS education for all employees, each operating site provides necessary preliminary education. We also clearly inform employees of EHS-related targets and actual figures to effectively motivate their active involvement in EHS activities.

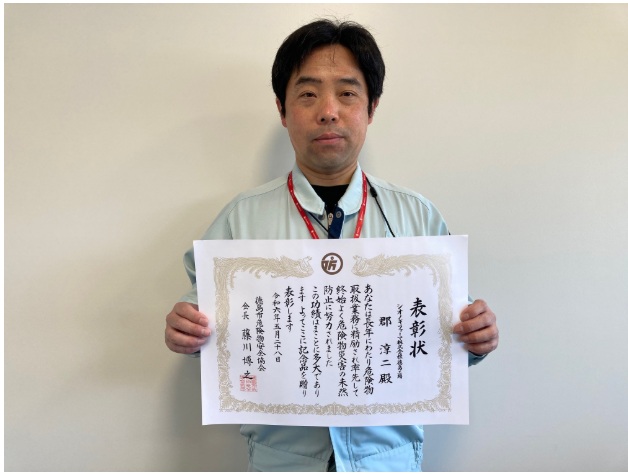

Commendation

2024 Tokushima City Harardous Safety Association Outsanding Employee: Junji Koori

Since joining the company, Mr. Koori has been engaged for many years in handling hazardous materials in the manufacturing department. Through proper handling of such materials, He has contributed to accident prevention, served as a role model for other employees, and has been recognized for his achievements.