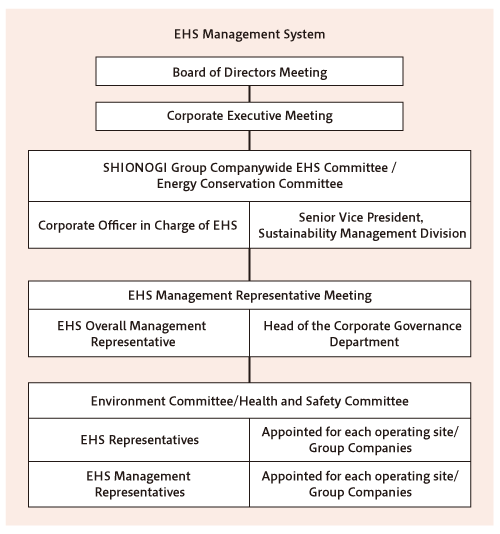

Environmental Governance

Environmental Governance Structure

To further strengthen the supervisory function of the Board of Directors over executive management and to focus on mid- to long-term company-wide strategies that balance stakeholder interests, SHIONOGI has decided to establish a company with an Audit and Supervisory Committee to bolster the oversight of executive management and focus discussions on critical mid- to long-term corporate strategies that balance stakeholder interests.

For details, see the Corporate Governance page

The Environmental, Health, and Safety (EHS) initiatives of the SHIONOGI Group are overseen by the Chief EHS Officer, appointed as the Senior Executive Officer of Sustainability Management. The SHIONOGI Group Companywide EHS Committee, chaired by the Chief EHS Officer, includes representatives from each operating site and the presidents of the group companies, all of whom serve as EHS officers. The committee discusses environmental materiality, sets annual EHS action targets, and reviews progress and activities through management reviews. Additionally, the Energy Conservation Committee, chaired by the Chief EHS Officer, develops draft targets for energy conservation and global warming countermeasures, oversees progress toward climate change goals, and assesses compliance with legal regulations.

The EHS Group of the Corporate Governance Department oversees the operation of these committees and the practical implementation of EHS activities in cooperation with the group operating sites. Matters of significant impact on management are deliberated at the Corporate Executive Meeting and decided by the Board of Directors, with advice sought from the Board as necessary.

Environmental/Occupational Health and Safety Management Systems (EHSMSs)

ISO 14001 and ISO 45001 Certified Sites and Initial Registration

Settsu Plant |

Kanegasaki Plant |

Tokushima Plant |

Itami Plant |

|

|---|---|---|---|---|

ISO 14001 |

Mar. 2021 |

Oct. 2022 |

Nov.2001 |

Apr. 2006 |

ISO 45001 |

Mar. 2018 |

Jul. 2015 |

Feb.2022 |

Apr. 2025 |

Certification Rate for Factories (Based on Energy Consumption)

Japan |

Global |

|

|---|---|---|

ISO 14001 |

97.9% |

92.3% |

ISO 45001 |

97.9% |

92.3% |

Audits

Audit Standard |

Audit Organization |

Audited Organization |

|---|---|---|

ISO 14001/ISO 45001 Requirements |

External audit body or own site |

Pharmaceutical manufacturing sites with ISO certification |

PSCI Principles |

SHIONOGI Group or external audit company |

Pharmaceutical manufacturing sites (SHIONOGI Group and suppliers) |

AMRIA Antibiotic Manufacturing Standard |

SHIONOGI Group or external audit company |

Antimicrobial manufacturing sites (SHIONOGI Group and suppliers) |

SHIONOGI Group EHS Management Regulations |

SHIONOGI Group or own site |

SHIONOGI Group sites (excluding ISO-certified sites) |

Furthermore, by using EcoVadis, SHIONOGI evaluates key suppliers based on global standards by reviewing the EHS-related components of the EcoVadis assessments.

For details, see the Supply Chain Management page.

Emergency Preparedness

SHIONOGI Group Enterprise Risk Management Policy prioritizes the protection of human life and the assurance of safety. The policy includes swiftly minimizing damage and effectively preventing the recurrence of incidents. To address risks such as earthquakes, pandemics, and corporate scandals, SHIONOGI has developed specific guidelines and response manuals focused on respect for human life, community contribution, and business continuity. To ensure ongoing preparedness, communication and reporting systems are specifically established, along with regular emergency drills and procedure reviews. In FY2024, disaster drills simulating emergencies such as tsunamis caused by earthquakes and fires were conducted based on the circumstances of each site.

A detailed business continuity plan is in place to ensure stable product supply and continuous service provision to medical institutions even during emergencies.

For details, see the Risk Management page.

Education

Theme |

Completion Rate |

Period |

|---|---|---|

SHIONOGI Group EHS Management, Environmental Materiality, EHS Action Targets |

93% (4,234/4,549 employees) |

July 10, 2024–August 20, 2024 |