Pollution Prevention

Pollution Prevention Initiatives

Prevention of Air, Water, and Soil Pollution

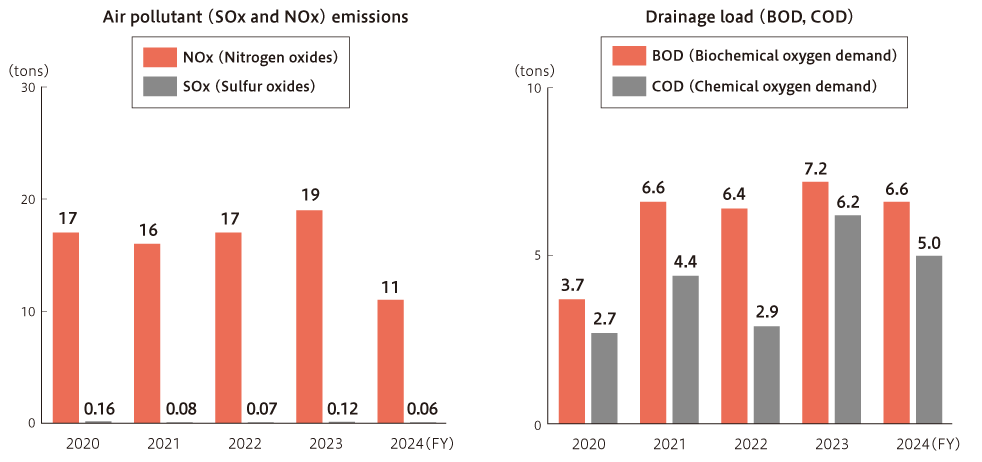

To prevent air pollution, SHIONOGI strictly observes the regulatory values for NOx, SOx, and particulate matter. In FY2014, we completed a fuel conversion from heavy oil, which contains many impurities, to liquefied natural gas at the Kanegasaki Plant, thereby achieving a significant reduction in SOx emissions. Moreover, to prevent wastewater contamination in sewers and public waters, we set voluntary criteria for pollutants, which are stricter than those imposed by related laws and regulations, and carry out round-the-clock monitoring of wastewater using TOC*1 meters and oil content monitoring devices. In particular, at the Kanegasaki Plant, the Tokushima Plant, and the Aburahi Research Center, where wastewater is released into rivers—which are public waters—from operating sites, wastewater is treated and purified at the facilities before it is released into nearby rivers.

The Kanegasaki Plant, which uses large quantities of chemical substances, sets voluntary criteria for soil pollution and takes periodic measurements. The measurements are consistently below the applicable environmental standard values.

Compliance with Relevant Laws and Regulations

Environmental regulations cover a wide range of areas, including waste management, energy management, air pollution and water contamination prevention, and chemical substance management. Information regarding amendments to laws and regulations is shared with each business site, which ensures thorough compliance through education and the development of manuals. In addition, regular evaluations are conducted to assess compliance status. Similarly, compliance with laws and regulations related to occupational health and safety, as well as regular evaluations, are also conducted.

SHIONOGI has not experienced any lawsuits or fines related to environmental or occupational health and safety issues in the past because of these initiatives.

Trends in the Number of Cases Exceeding Emission Standards (Regulatory Values)

| FY | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Shionogi & Co., Ltd. | 0 | 0 | 0 | 0 | 3 |

| Group companies | 1 | 0 | 0 | 0 | 0 |

Trends in the Number of Environmental Complaints

| FY | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Shionogi & Co., Ltd. | 0 | 2 | 1 | 0 | 0 |

| Group companies | 0 | 1 | 0 | 0 | 2 |